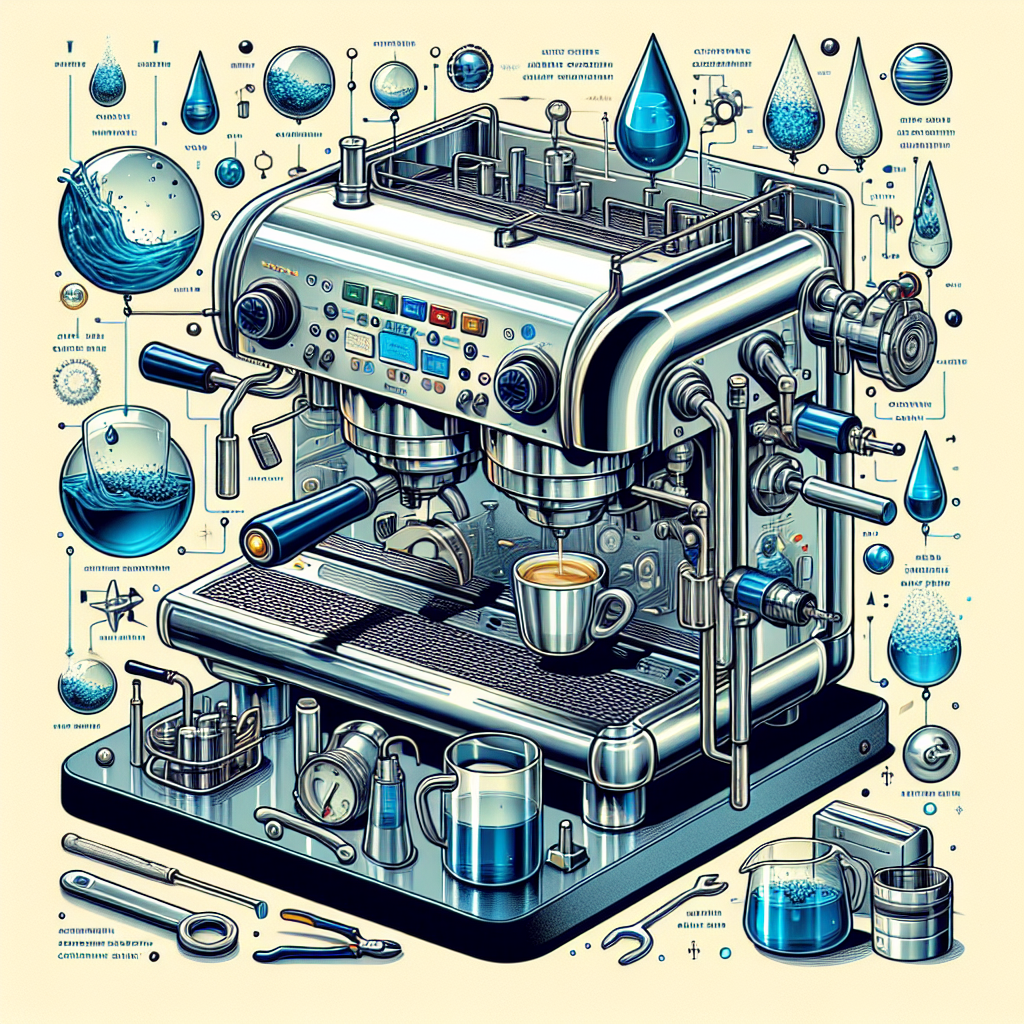

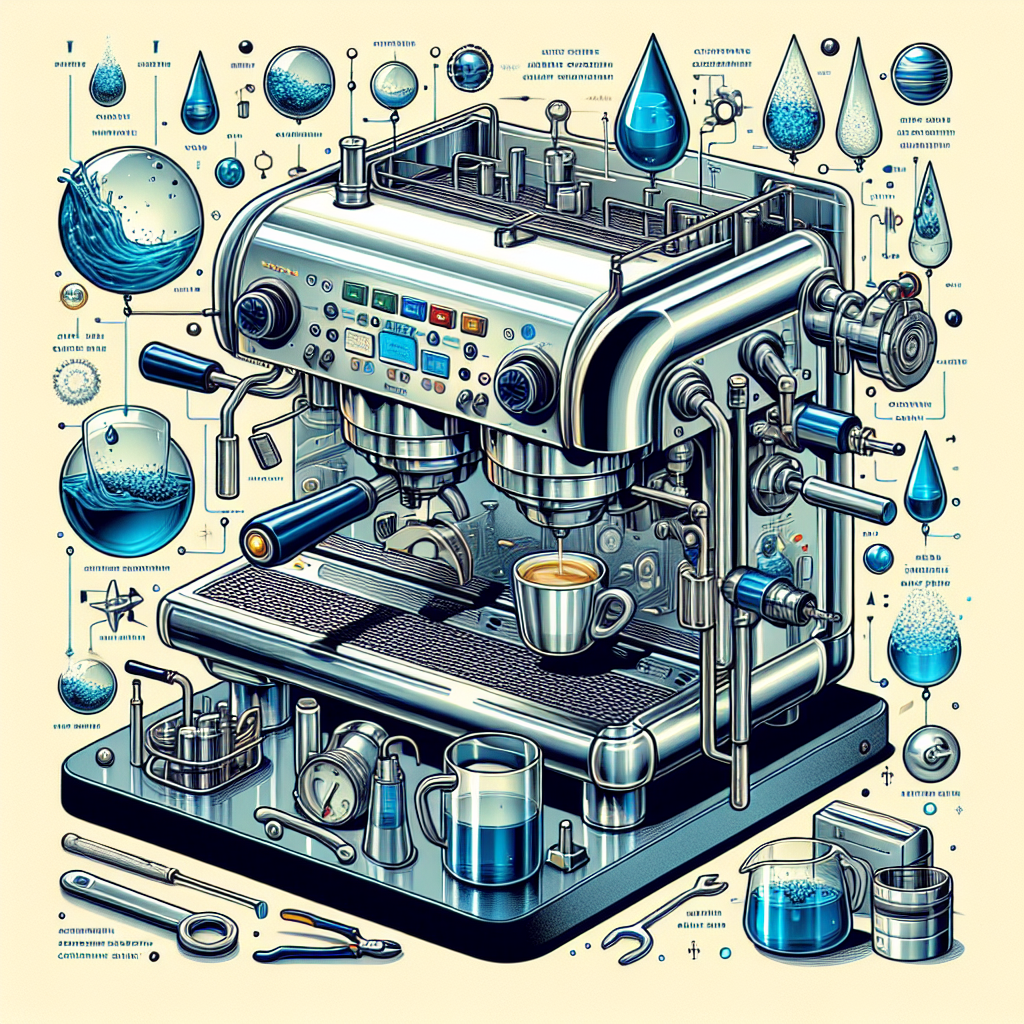

You may not realize it, but the water you use in your stainless steel espresso machine can have a significant impact on its performance and lifespan. Whether you’re a barista in a bustling café or a coffee lover at home, understanding the relationship between water quality and your espresso machine is essential. This article explores the effects of water quality on stainless steel espresso machines, uncovering the potential problems that can arise and offering practical tips for maintaining the optimal brewing environment. Prepare to discover how the quality of your water can make a world of difference in your espresso experience.

Corrosion Potential

Effect of water hardness

One of the crucial factors that impact the longevity and performance of stainless steel espresso machines is the hardness of the water used. Hard water contains high levels of minerals such as calcium and magnesium. These minerals can accumulate over time, causing scaling and deposits in the machine’s internal components. Additionally, the minerals in hard water can react with the stainless steel, leading to corrosion and the deterioration of the machine’s structural integrity.

To mitigate the negative effects of water hardness, it is advisable to use water that has been properly treated or softened. Softening the water helps to reduce the mineral content, minimizing the chances of scale buildup and corrosion. Regular descaling of the machine is also essential to remove any accumulated mineral deposits and maintain its performance and longevity.

Effect of water pH

Water pH is another critical factor that can significantly impact stainless steel espresso machines. The pH level indicates the acidity or alkalinity of the water. Water with a high pH (alkaline water) can cause corrosion and damage to the machine’s internal components. On the other hand, water with a low pH (acidic water) can lead to leaching of metals from the stainless steel, affecting the taste and quality of the espresso.

It is recommended to use water with a pH level between 6.5 and 7.5 for optimal performance and longevity of the espresso machine. Regular monitoring and adjustment of the water pH can help prevent any adverse effects on the machine and ensure a consistent brewing experience.

Effect of chlorine content

Chlorine is commonly added to water supplies as a disinfectant. While it plays an important role in ensuring water safety, high chlorine levels can have adverse effects on stainless steel espresso machines. Chlorine is a powerful oxidizer and can cause corrosion or pitting in the stainless steel, leading to leaks and reduced machine performance.

To minimize the impact of chlorine on the espresso machine, it is advisable to use water that has been properly filtered or treated to remove chlorine. Alternatively, allowing the water to sit for a while before brewing can help dissipate the chlorine content. Regular cleaning and maintenance of the machine, including the use of appropriate descaling agents, can also help protect against the detrimental effects of chlorine.

Scaling and Deposits

Effect of mineral content

The mineral content in the water used for brewing espresso can have a significant impact on the formation of scaling and deposits in stainless steel espresso machines. Water with high levels of minerals, such as calcium and magnesium, tends to be “hard” and can lead to the accumulation of scale on internal components. This scale buildup can affect the machine’s performance, leading to reduced water flow and brew temperatures, as well as clogged pipes and valves.

Using water that has been properly treated to reduce the mineral content is crucial in preventing scaling issues. Water softeners or filtration systems can help remove or reduce the minerals responsible for forming scale. Regular descaling of the espresso machine is also essential to remove any existing scale buildup and maintain optimal performance.

Effect of silica content

Silica is another mineral commonly found in water that can contribute to scaling and deposits in stainless steel espresso machines. High levels of silica can result in the formation of insoluble silicates, which can accumulate on heating elements, boilers, and other internal surfaces. This buildup can lead to reduced efficiency, increased energy consumption, and potentially cause damage to the machine’s components.

To prevent silica-related scaling issues, it is recommended to use water that has been properly treated or filtered to remove or reduce silica content. Regular descaling and cleaning of the machine’s internal components, particularly those prone to silica buildup, are crucial to maintaining optimal performance and prolonging the machine’s lifespan.

Effect of dissolved solids

Dissolved solids in water refer to any substances that are present in a dissolved form, including minerals, salts, and organic compounds. High levels of dissolved solids can contribute to scaling and deposits in stainless steel espresso machines, affecting their overall performance and efficiency. These deposits can restrict water flow, reduce heat transfer, and potentially lead to clogged or malfunctioning components.

Using water with low levels of dissolved solids is essential in ensuring the longevity and performance of the espresso machine. This can be achieved through the use of appropriate water filtration or treatment systems. Regular descaling and cleaning of the machine is also crucial to remove any accumulated deposits and maintain its efficiency.

Steam Quality

Effect of water impurities

The quality of steam produced by an espresso machine is directly influenced by the impurities present in the water. Impurities such as minerals, chemicals, and organic matter can contaminate the steam and negatively impact the taste, aroma, and overall quality of the espresso. Additionally, these impurities can cause clogging or damage to the steam wand, reducing its functionality.

To ensure high-quality steam, it is essential to use water that has been properly filtered or treated to remove impurities. Water filtration systems or reverse osmosis technology can effectively remove most contaminants, resulting in clean and pure steam. Regular maintenance and cleaning of the steam wand are also necessary to prevent any buildup and ensure consistent performance.

Effect of temperature

The temperature of the water used for brewing espresso plays a crucial role in steam quality. Water that is too cold may not generate sufficient steam, leading to weak milk frothing and inconsistent espresso extraction. On the other hand, water that is too hot can cause the steam to become too dense and overpowering, resulting in uneven extraction and potentially burnt flavors.

It is important to maintain the correct water temperature for optimal steam quality. Espresso machines with temperature control mechanisms or adjustable settings are highly recommended to achieve the desired temperature range. Regular calibration and monitoring of the machine’s temperature accuracy can help ensure consistent steam quality and enhance the overall brewing experience.

Effect of steam pressure

Steam pressure is another vital factor that influences the quality of steam produced by an espresso machine. Insufficient steam pressure can result in incomplete extraction and thin crema, while excessive steam pressure can cause over-extraction and bitter flavors. Proper control and regulation of the steam pressure are essential for achieving the desired espresso characteristics.

Espresso machines with adjustable steam pressure settings or features like PID (Proportional-Integral-Derivative) control offer more precise control over the steam pressure. Regular maintenance and servicing of the machine, including checking for any leaks or issues with pressure regulation, are crucial for ensuring consistent steam pressure and optimal steam quality.

Lifetime and Performance

Effect on heating elements

The quality of water used in stainless steel espresso machines can have a significant impact on the lifespan and performance of the heating elements. High mineral content, particularly calcium and magnesium, can lead to the accumulation of scale on the heating elements. This scale buildup reduces the efficiency of heat transfer, causing the heating elements to work harder and potentially leading to overheating and premature failure.

To protect the heating elements and prolong their lifespan, it is essential to use water with low mineral content. Regular descaling and cleaning of the machine, specifically targeting the heating elements, help remove any scale buildup. Additionally, using water that has been properly treated or filtered to reduce mineral content can significantly contribute to the long-term performance and durability of the heating elements.

Effect on pump performance

The water quality used in espresso machines also directly influences the performance and lifespan of the pump. High mineral content can lead to the formation of scale on the pump’s internal components, restricting water flow and putting additional strain on the pump motor. Over time, this can lead to reduced water pressure, inconsistent extraction, and potential pump failure.

Regular descaling and maintenance of the pump are crucial in preventing any adverse effects from water impurities. Water filtration or treatment systems that remove minerals and other impurities can help reduce the likelihood of scale formation. Monitoring and adjusting water quality parameters, such as hardness and pH, in combination with regular pump servicing, are essential for maintaining optimal pump performance and extending its lifespan.

Effect on overall machine efficiency

The overall efficiency of a stainless steel espresso machine is significantly influenced by the quality of water used. Water impurities, such as minerals and organic matter, can accumulate over time and cause scaling, internal blockages, and component malfunction. These issues affect the machine’s ability to heat water, maintain temperature consistency, and deliver optimal pressure for espresso extraction.

To ensure optimal machine efficiency, it is crucial to use water that has been properly treated or filtered to remove impurities. Regular maintenance, cleaning, and descaling are essential to prevent any buildup that might compromise the machine’s performance. Additionally, monitoring and adjusting water quality parameters, such as hardness, pH, and dissolved solids, are key in maintaining consistent and efficient brewing processes.

Maintenance Requirements

Effect on frequency of descaling

Water quality directly affects the frequency at which descaling is required for stainless steel espresso machines. Hard water, high in mineral content, is more prone to scaling, which necessitates regular descaling to remove the accumulated deposits. The harder the water, the more frequently descaling needs to be performed.

Using water with low mineral content, achieved through proper treatment or filtration, can help reduce the frequency of descaling. Additionally, regular monitoring of water hardness, as well as temperature and pressure adjustments, can help prevent excessive scale buildup and extend the intervals between descaling procedures.

Effect on frequency of cleaning

The quality of water used in stainless steel espresso machines also affects the frequency of routine cleaning. Water impurities can lead to the buildup of residues on internal components and surfaces, requiring more frequent cleaning to maintain hygiene standards and optimal performance.

Water filtration or treatment systems that remove impurities are effective in reducing the frequency of cleaning. However, regular cleaning and maintenance should still be performed to remove any accumulated residues and ensure the machine’s cleanliness and functionality. Following the manufacturer’s recommendations for cleaning procedures and intervals is vital for maintaining the espresso machine’s performance and longevity.

Effect on replacement/maintenance of parts

The quality of water used plays a significant role in determining the frequency and extent of parts replacement or maintenance required for stainless steel espresso machines. Water impurities, particularly minerals, can cause corrosion, scaling, and other issues with internal components, leading to malfunctions or failures.

Using water with low mineral content reduces the risk of these issues and helps prolong the lifespan of machine components. Regular maintenance, including proper cleaning and descaling, is essential to prevent any potential damage or deterioration. By ensuring water quality meets recommended standards, espresso machine owners can minimize the frequency of parts replacement and maintenance, resulting in long-term cost savings and machine reliability.

Taste and Aroma

Effect on coffee flavor

The quality of water used for brewing has a direct impact on the taste and flavor profile of the espresso. Water impurities, such as minerals, chemicals, and organic matter, can alter the coffee’s flavor, resulting in off-notes, bitterness, or a dull taste. Additionally, high mineral content can affect the solubility of coffee compounds, affecting the extraction process and overall flavor quality.

Using water that is free from impurities is crucial in preserving the natural flavors and characteristics of the coffee. Proper filtration or treatment systems can remove undesired elements, resulting in a purer, cleaner taste. Additionally, regular maintenance and cleaning of the espresso machine, combined with proper water quality control, help ensure consistent and enjoyable coffee flavor.

Effect on crema quality

Crema, the rich, golden layer that forms on top of a well-brewed espresso, is greatly influenced by the quality of water used. Water impurities can negatively impact crema formation, resulting in a thin, unstable layer or even the absence of crema altogether. Additionally, excessive mineral content can affect the texture and color of the crema, leading to an inferior visual and sensory experience.

Using water of high quality, free from impurities, helps achieve the desired crema characteristics. Proper filtration or treatment systems can remove impurities and improve the texture and stability of the crema. Maintaining optimal water quality and regularly cleaning the espresso machine’s components, such as the brew head and portafilter, are essential for consistently achieving excellent crema quality.

Effect on aroma intensity

Water quality also influences the aroma intensity of the espresso. Impurities present in the water can impart unwanted odors or affect the extraction process, resulting in a diminished or altered aroma. The minerals found in hard water, for example, can interfere with the release of aromatic compounds during brewing.

Using properly filtered or treated water helps ensure a clean and pure aroma in the brewed espresso. Water with low mineral content allows the aroma compounds to fully express themselves, enhancing the overall sensory experience. Regular cleaning and maintenance of the espresso machine, along with monitoring and adjusting water quality parameters, are essential in preserving the desired aroma intensity.

Quality Consistency

Effect on espresso extraction

Water quality is one of the key factors influencing the consistency of espresso extraction. Impurities in the water can alter the chemical balance, affecting the solubility of coffee compounds and extraction efficiency. Inconsistent extraction can lead to variations in taste, strength, and overall quality from shot to shot.

Using water of high quality, free from impurities, is crucial in achieving consistent extraction results. Proper water filtration or treatment systems can help remove unwanted elements and promote uniform extraction. Regular calibration and monitoring of the espresso machine’s brewing parameters, in combination with maintaining optimal water quality, are vital for ensuring consistent and repeatable extraction performance.

Effect on shot consistency

The quality of water used in an espresso machine has a direct impact on the consistency of individual shots. Water impurities can lead to variations in brewing parameters, such as temperature, pressure, and flow rate, resulting in inconsistent shot volumes, flavors, and crema quality.

Using water that has been properly treated or filtered to remove impurities helps achieve shot-to-shot consistency. The use of espresso machines with temperature and pressure control mechanisms allows for more precise adjustments and greater shot consistency. Regular maintenance, cleaning, and descaling of the machine, combined with careful monitoring of water quality, contribute to consistent shot quality and a more enjoyable brewing experience.

Effect on brewing time

Water quality can also affect the brewing time of espresso. Water impurities, particularly mineral content, can impact the flow rate and extraction speed. Excessive mineral content, for example, can cause clogging or restrict water flow, leading to longer brewing times and potential under-extraction.

Using water with low mineral content is essential to ensure consistent brewing times. Proper filtration or treatment systems can help remove impurities and maintain optimal flow rates. Regular cleaning and maintenance of the espresso machine, along with monitoring and adjusting water quality parameters, are crucial for consistent brewing times and optimal extraction results.

Machine Durability

Effect on stainless steel lifespan

The quality of water used in stainless steel espresso machines directly impacts the lifespan and durability of the machine’s stainless steel components. Water impurities, such as minerals and chemicals, can cause corrosion, pitting, or staining on the stainless steel surfaces, compromising their integrity and longevity.

Using water that has been properly treated or filtered to remove impurities is crucial in preserving the stainless steel surfaces. Regular cleaning and maintenance of the machine, including the use of appropriate descaling agents and stainless steel cleaners, help prevent any damage or deterioration. Proper water quality control, combined with routine machine care, extends the lifespan of the stainless steel parts, ensuring the overall durability and performance of the espresso machine.

Effect on gasket durability

The gaskets in an espresso machine are crucial for maintaining proper water and steam seals. Water quality can significantly impact the durability and effectiveness of these gaskets. High mineral content can cause scaling and buildup around the gaskets, compromising their functionality and leading to leaks or improper pressure regulation.

Using water with low mineral content is essential in maximizing gasket durability. Regular cleaning, descaling, and maintenance of the machine, paying specific attention to the gaskets, are vital for preserving their integrity. Following the manufacturer’s recommendations for gasket replacements and proper machine care helps ensure long-lasting gaskets and optimal machine performance.

Effect on valve longevity

Water quality also affects the longevity and functionality of valves in stainless steel espresso machines. Water impurities, particularly minerals, can accumulate and cause clogging or restriction in the valves, leading to reduced water flow control and potential valve failure.

Using water that has been adequately filtered or treated to remove impurities is key in protecting the valves from this type of damage. Regular cleaning and maintenance of the machine, including descaling and checking for any signs of valve blockage, help preserve their efficiency and extend their lifespan. Proper water quality control, combined with routine machine care, ensures optimal valve performance and longevity.

Health and Safety

Effect on bacterial growth

Water quality has important implications for bacterial growth and hygiene in stainless steel espresso machines. Impurities, organic matter, and inadequate water treatment can create an environment conducive to bacterial growth, potentially compromising the safety and quality of the espresso produced.

Using water that has been appropriately treated or filtered to remove impurities minimizes the risk of bacterial growth. Regular cleaning, sanitation, and maintenance of the machine, including thorough cleaning of water reservoirs and pipes, are essential for maintaining optimal hygiene. Following recommended cleaning procedures and guidelines for machine care helps ensure a safe and bacteria-free brewing environment.

Effect on food safety standards

The quality of water used in stainless steel espresso machines is paramount in ensuring compliance with food safety standards. Water impurities, including microorganisms, chemicals, and contaminants, can pose health risks and violate regulatory requirements.

Using water that meets the recommended quality standards, properly treated or filtered to remove impurities, is crucial for food safety compliance. Regular monitoring and testing of water quality parameters, in combination with proper maintenance and cleaning of the espresso machine, contribute to maintaining a safe and hygienic brewing environment. Adhering to food safety regulations and guidelines ensures the safety and well-being of customers and upholds industry standards.

Effect on machine maintenance safety

Water quality also has implications for machine maintenance safety. The presence of impurities, chemicals, or scale buildup can create hazardous conditions and compromise the safety of the maintenance personnel.

Using water that is free from harmful contaminants reduces the risk of potential hazards during machine maintenance. Proper cleaning and descaling procedures, following manufacturer’s guidelines, help remove any accumulated impurities and ensure a safe working environment. Regular maintenance checks for any signs of corrosion, leaks, or deterioration, combined with proper water quality control, contribute to a safe and secure espresso machine maintenance routine.

Cost and Efficiency

Effect on energy consumption

The quality of water used in an espresso machine can impact its energy consumption. High mineral content, resulting in scale buildup, reduces the efficiency of heat transfer in the machine. This requires the heating elements and other components to work harder, leading to increased energy consumption.

Using water with low mineral content helps minimize scale formation and optimize energy efficiency. Proper filtration or treatment systems can effectively remove or reduce minerals responsible for scale buildup. Regular cleaning and descaling of the machine, as well as monitoring and adjusting water quality parameters, contribute to lower energy consumption and reduced operating costs.

Effect on machine lifespan

Water quality significantly influences the lifespan of stainless steel espresso machines. Water impurities, such as minerals, chemicals, and contaminants, can cause corrosion, scaling, and damage to internal components over time. This can result in frequent breakdowns, reduced machine functionality, and premature failure.

Using water of high quality, free from impurities, is essential in ensuring the longevity of the espresso machine. Proper filtration or treatment systems help remove unwanted elements and minimize the risk of damage. Regular maintenance, cleaning, and descaling, along with monitoring and adjusting water quality parameters, contribute to a longer machine lifespan and reduce the need for frequent replacements or repairs.

Effect on long-term operating costs

Water quality has a direct impact on the long-term operating costs associated with stainless steel espresso machines. Higher mineral and impurity levels can result in increased maintenance requirements, frequent descaling, and more frequent parts replacements. This can lead to higher maintenance and repair costs, as well as increased downtime and lost revenue.

Using water that has been properly treated or filtered to remove impurities helps reduce long-term operating costs. By minimizing the frequency of maintenance, descaling, and parts replacements, espresso machine owners can save on expenses. Regular monitoring and adjustment of water quality parameters, in combination with proper machine care and maintenance, contribute to cost efficiency and maximize the return on investment.

In conclusion, the quality of water used in stainless steel espresso machines has a profound impact on various aspects, including corrosion potential, scaling and deposits, steam quality, lifetime and performance, maintenance requirements, taste and aroma, quality consistency, machine durability, health and safety, and cost and efficiency. Proper water filtration or treatment, regular maintenance, and adherence to recommended cleaning procedures are essential to maximize performance, longevity, and the overall brewing experience. By understanding the effects of water quality and taking appropriate measures, espresso machine owners can ensure optimal efficiency, taste, and safety while minimizing long-term costs and maintaining the highest standards.