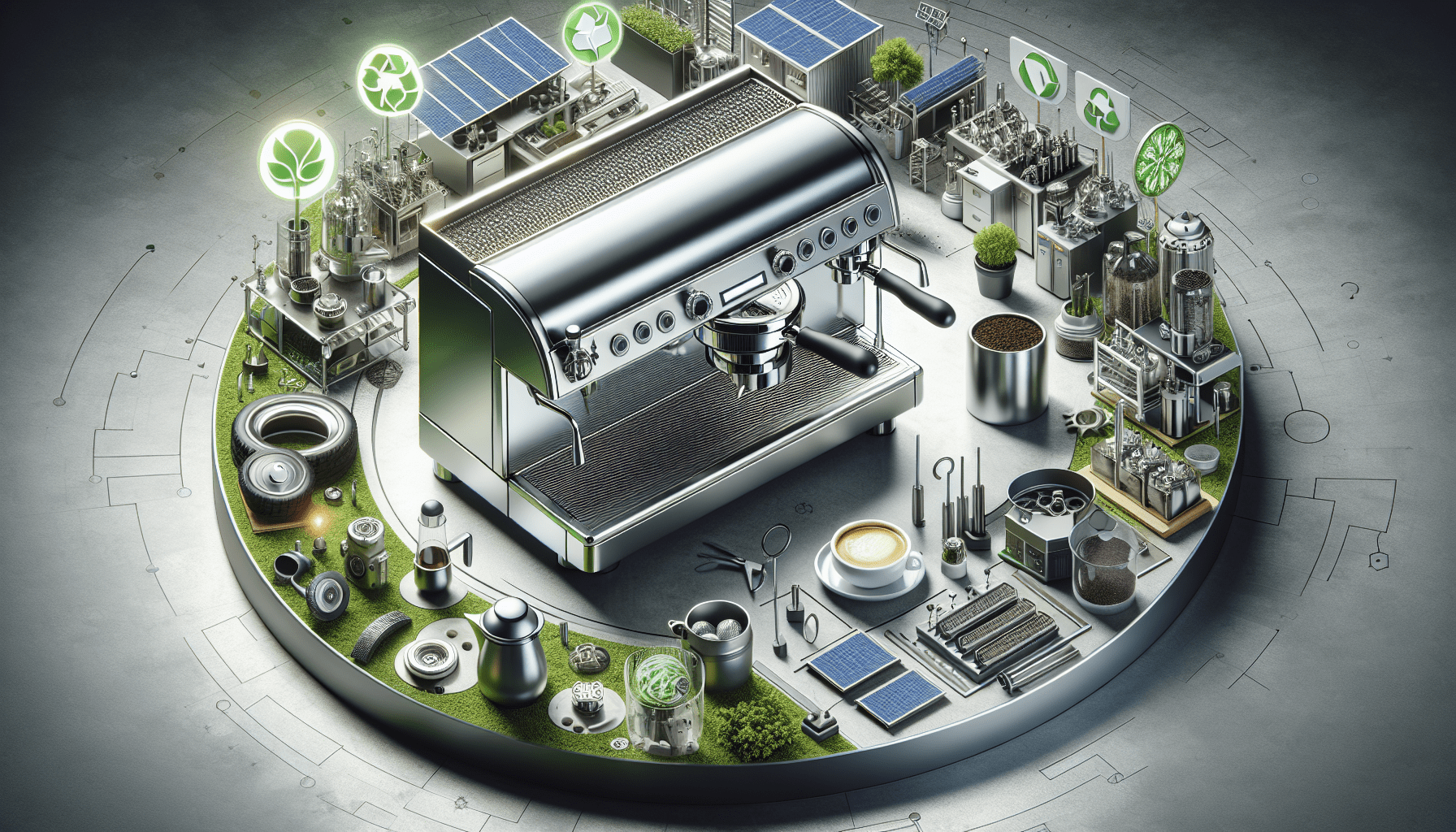

In the world of coffee lovers, the quest for the perfect espresso machine is an ongoing pursuit. However, as we continue to prioritize sustainability and the conservation of our planet, the focus has shifted towards environmentally friendly manufacturing processes. With the rise of stainless steel espresso machines, a new era of sustainable manufacturing has emerged. This article explores the future of stainless steel espresso machines and how they are revolutionizing the industry by integrating eco-friendly practices, ensuring a guilt-free coffee experience for all.

Increased Efficiency and Energy Savings

Use of advanced technology

In order to improve efficiency and reduce energy consumption, manufacturers are utilizing advanced technology in the production of stainless steel espresso machines. This includes the use of energy-efficient motors, intelligent control systems, and advanced automation. By incorporating these technologies, manufacturers are able to optimize the performance of their machines, resulting in increased energy savings. Not only does this benefit the environment by reducing greenhouse gas emissions, but it also helps consumers save on their energy bills.

Optimization of production processes

Another key aspect of sustainable manufacturing is the optimization of production processes. Manufacturers are constantly looking for ways to streamline operations and reduce waste. By implementing lean manufacturing principles, they are able to identify and eliminate unnecessary steps in the production process, resulting in improved efficiency and reduced energy consumption. Additionally, manufacturers are investing in research and development to develop more energy-efficient production methods. This includes the use of renewable energy sources, such as solar power, to power their manufacturing facilities.

Reduction in energy consumption

Manufacturers are also focusing on reducing energy consumption throughout the lifecycle of stainless steel espresso machines. This includes not only the energy used during the manufacturing process, but also the energy consumed during use. By designing machines with energy-saving features, such as automatic shut-off functions and low-power modes, manufacturers are able to minimize the energy required to operate the machines. Additionally, manufacturers are exploring ways to improve the energy efficiency of their machines by incorporating insulation and temperature control mechanisms, which can help to reduce heat loss and energy waste.

Environmentally Friendly Materials

Use of sustainably sourced stainless steel

One of the key components of sustainable manufacturing is the use of environmentally friendly materials. In the case of stainless steel espresso machines, manufacturers are increasingly sourcing their stainless steel from sustainable suppliers. This means that the stainless steel is produced using methods that minimize environmental impact, such as using recycled materials or implementing water and energy conservation measures during production. By using sustainably sourced stainless steel, manufacturers can ensure that their machines have a lower environmental footprint, while still maintaining the quality and durability that customers expect.

Replacement of harmful materials

In addition to using sustainable stainless steel, manufacturers are also making efforts to replace harmful materials in their machines. This includes the elimination of toxic chemicals, such as lead and mercury, which can be harmful to both human health and the environment. Manufacturers are using alternative materials that are non-toxic and have a lower environmental impact. By using safer materials, manufacturers can ensure that their machines are not only safe for consumers to use, but also environmentally friendly.

Recyclability of components

Another important aspect of environmentally friendly manufacturing is the recyclability of components. Manufacturers are designing their machines with recyclability in mind, making it easier for consumers to dispose of their machines in an environmentally responsible manner. This includes using materials that can be easily separated and recycled, as well as working with recycling programs to ensure that components are properly disposed of at the end of their life cycle. By designing machines with recyclability in mind, manufacturers are able to reduce the amount of waste sent to landfills and minimize the overall environmental impact of their products.

Reduced Waste Generation

Implementation of lean manufacturing principles

One of the key strategies for reducing waste in manufacturing is the implementation of lean manufacturing principles. This involves identifying and eliminating waste in all aspects of the production process, including materials, time, and energy. By streamlining operations and eliminating unnecessary steps, manufacturers are able to minimize waste generation and improve efficiency. This not only benefits the environment by reducing the amount of waste sent to landfills, but it also helps manufacturers to reduce costs and improve their overall profitability.

Minimization of packaging waste

Packaging waste is a significant concern in manufacturing, particularly in the food and beverage industry. In the case of stainless steel espresso machines, manufacturers are taking steps to minimize packaging waste. This includes using packaging materials that are recyclable and using the minimum amount of packaging necessary to protect the machines during transportation. Additionally, manufacturers are exploring alternative packaging solutions, such as reusable containers or biodegradable materials, to further reduce the environmental impact of their packaging.

Reuse and recycling of production waste

In addition to minimizing waste generation, manufacturers are also focusing on the reuse and recycling of production waste. This includes implementing waste management systems that separate and recycle materials, such as metal shavings or excess sheet metal, that are generated during the production process. By reusing or recycling these materials, manufacturers are able to reduce the amount of waste sent to landfills and conserve valuable resources. This not only benefits the environment, but it also helps to reduce manufacturing costs and improve overall sustainability.

Water Conservation

Development of water-saving features

Water is a valuable resource, and manufacturers are recognizing the importance of water conservation in sustainable manufacturing. In the case of stainless steel espresso machines, manufacturers are developing water-saving features that minimize water usage during operation. This includes the use of efficient water filters and cartridges that reduce the need for frequent water changes, as well as technology that optimizes water flow to minimize waste. By designing machines with water-saving features, manufacturers can help customers save on water usage and contribute to overall water conservation efforts.

Efficient water management systems

In addition to developing water-saving features, manufacturers are also implementing efficient water management systems in their manufacturing processes. This includes the use of closed-loop systems that recirculate and treat water used in production, reducing the amount of fresh water needed. Additionally, manufacturers are investing in water treatment technologies that remove contaminants and pollutants from wastewater, ensuring that it can be safely discharged or reused. By implementing efficient water management systems, manufacturers are able to minimize their impact on local water sources and ensure the responsible use of this valuable resource.

Recycling and treatment of water used in manufacturing

To further reduce their water footprint, manufacturers are also implementing recycling and treatment systems for water used in the manufacturing process. This includes capturing and treating wastewater to remove impurities and contaminants, allowing it to be reused in manufacturing operations. By recycling and treating water, manufacturers are able to minimize the amount of fresh water needed for production, reducing their overall water consumption and contributing to water conservation efforts. Additionally, this helps to reduce the environmental impact of their operations by preventing the release of contaminated wastewater into local water sources.

Lifecycle Assessment

Comprehensive analysis of environmental impacts

To ensure the overall sustainability of stainless steel espresso machines, manufacturers are conducting comprehensive lifecycle assessments to evaluate their environmental impacts. This involves analyzing the entire lifecycle of the machines, from raw material extraction to end-of-life disposal, to identify areas of improvement and potential environmental hotspots. By conducting these assessments, manufacturers can gain a better understanding of the specific environmental impacts of their machines and make informed decisions to minimize their overall carbon footprint.

Consideration of carbon footprint

One of the key aspects of lifecycle assessments is the consideration of carbon footprint. Manufacturers are evaluating the greenhouse gas emissions associated with the production, use, and disposal of stainless steel espresso machines. By identifying areas of high emissions, manufacturers can implement strategies to reduce their carbon footprint, such as using renewable energy sources, optimizing the energy efficiency of their machines, and promoting responsible end-of-life disposal practices. By considering the carbon footprint of their machines, manufacturers can take proactive steps to mitigate their environmental impact and contribute to global efforts to combat climate change.

Evaluation of entire product lifecycle

In addition to considering environmental impacts and carbon footprint, manufacturers are evaluating the entire product lifecycle of stainless steel espresso machines. This includes assessing factors such as resource consumption, energy usage, waste generation, and potential environmental risks. By evaluating the entire product lifecycle, manufacturers can identify opportunities for improvement and implement strategies to minimize environmental impacts throughout the entire lifespan of the machines. This holistic approach ensures that manufacturers are addressing all aspects of sustainability and working towards continuous improvement in their manufacturing processes.

Improved Supply Chain Sustainability

Selection of eco-friendly suppliers

Sustainable manufacturing goes beyond the production process itself and extends to the entire supply chain. Manufacturers are taking steps to select eco-friendly suppliers who share their commitment to sustainability. This includes sourcing materials from suppliers that adhere to responsible sourcing practices and have implemented environmental management systems. By working with eco-friendly suppliers, manufacturers can ensure that their entire supply chain is aligned with sustainable principles and minimize their overall environmental impact.

Implementation of fair trade practices

In addition to selecting eco-friendly suppliers, manufacturers are also implementing fair trade practices within their supply chain. This includes ensuring that workers throughout the supply chain are treated fairly and provided with safe working conditions. Manufacturers are committed to working with suppliers who follow ethical labor practices, such as fair wages and reasonable working hours. By promoting fair trade practices, manufacturers are not only supporting the well-being of workers but also contributing to the overall sustainability and social responsibility of their operations.

Reduction of transportation emissions

Transportation is a significant source of greenhouse gas emissions, and manufacturers are taking steps to reduce the environmental impact of their transportation activities. This includes optimizing transportation routes and modes to minimize distances traveled and maximize fuel efficiency. Manufacturers are also exploring alternative transportation methods, such as rail or sea, that have lower emissions compared to traditional road transport. By reducing transportation emissions, manufacturers can minimize their overall carbon footprint and contribute to efforts to mitigate climate change.

Worker Safety and Well-being

Implementation of ergonomic design principles

Worker safety and well-being are important considerations in sustainable manufacturing. Manufacturers are implementing ergonomic design principles in the development of stainless steel espresso machines to ensure the comfort and safety of workers during production. This includes designing machines with user-friendly interfaces, ergonomic handles, and adjustable components to minimize the risk of musculoskeletal injuries and strain. By prioritizing worker safety and well-being, manufacturers are not only fostering a healthy work environment, but also enhancing productivity and overall employee satisfaction.

Adherence to safety regulations

Manufacturers also prioritize adherence to safety regulations to ensure the well-being of their workers. This includes complying with occupational health and safety standards and providing the necessary training and protective equipment to employees. By maintaining a safe work environment, manufacturers can prevent accidents and injuries, reducing human suffering and improving the overall quality of work life. Additionally, adherence to safety regulations helps to build trust and credibility with employees, fostering a positive workplace culture.

Provision of a healthy work environment

In addition to ensuring worker safety, manufacturers are also committed to providing a healthy work environment for their employees. This includes promoting clean and well-ventilated workspaces, implementing proper waste management systems, and offering access to clean drinking water and sanitation facilities. By creating a healthy work environment, manufacturers can enhance the overall well-being of their employees, improving job satisfaction and productivity. Additionally, a healthy work environment contributes to the overall sustainability of operations by minimizing the risk of pollution and ensuring the responsible use of resources.

Longevity and Durability

Development of high-quality components

In order to promote longevity and durability, manufacturers are focusing on the development of high-quality components for their stainless steel espresso machines. This includes using premium materials and conducting rigorous testing to ensure that the components can withstand regular use and extended lifespans. By using high-quality components, manufacturers can minimize the need for frequent repairs or replacements, reducing waste and extending the overall lifespan of the machines. This not only benefits the environment by reducing the demand for new products but also provides customers with a reliable and long-lasting product.

Enhancement of product lifespan

Manufacturers are also enhancing the lifespan of stainless steel espresso machines through continuous improvement and innovation. By investing in research and development, manufacturers are able to identify opportunities to improve product design, performance, and reliability. This includes addressing common issues and weaknesses in previous product versions to ensure that the latest models are more durable and long-lasting. Additionally, manufacturers are offering repair and maintenance services to extend the lifespan of their machines, providing customers with cost-effective options to prolong the use of their products.

Repair and maintenance services

To further promote longevity and reduce waste, manufacturers are offering repair and maintenance services for stainless steel espresso machines. This includes providing access to spare parts, repair manuals, and technical support to enable customers to repair and maintain their machines. By offering repair and maintenance services, manufacturers can extend the lifespan of their machines and reduce the need for premature replacements. This not only benefits customers by providing them with cost-effective solutions, but also reduces waste and contributes to overall sustainability.

End-of-Life Disposal

Promotion of recycling initiatives

Proper end-of-life disposal is a crucial aspect of sustainable manufacturing. Manufacturers are actively promoting recycling initiatives to encourage customers to properly dispose of their stainless steel espresso machines. This includes providing information on local recycling facilities and participating in take-back programs to collect and recycle old machines. By encouraging recycling, manufacturers can ensure that valuable materials are recovered and reused, reducing the demand for new raw materials and minimizing the environmental impact of disposal.

Responsible disposal of hazardous components

In addition to promoting recycling, manufacturers are also committed to the responsible disposal of hazardous components found in stainless steel espresso machines. This includes working with certified disposal facilities and following applicable regulations to ensure that hazardous materials, such as batteries or electronic components, are properly handled and disposed of. By adhering to responsible disposal practices, manufacturers can prevent the release of harmful substances into the environment and protect human health.

Collection and refurbishment programs

To further reduce waste and promote sustainability, manufacturers are implementing collection and refurbishment programs for stainless steel espresso machines. This includes collecting old machines and refurbishing them for resale or donation. By refurbishing machines, manufacturers can extend their lifespan and provide consumers with affordable options without the need for new manufacturing. Additionally, collection programs ensure that machines are disposed of responsibly, preventing them from ending up in landfills and conserving valuable resources.

Customer Education and Engagement

Provision of product information on sustainability

Manufacturers are recognizing the importance of customer education and engagement in promoting sustainability. They are providing comprehensive product information on the environmental features and benefits of their stainless steel espresso machines. This includes information on the use of sustainable materials, energy-saving features, and end-of-life disposal options. By providing this information, manufacturers are empowering customers to make informed choices and understand the environmental impact of their purchases.

Promotion of eco-friendly practices

In addition to providing product information, manufacturers are actively promoting eco-friendly practices to their customers. This includes providing tips and recommendations on energy-saving techniques, such as using the machines in low-power modes or utilizing programmable settings. Manufacturers are also encouraging customers to reduce waste by using reusable coffee filters and composting coffee grounds. By promoting these practices, manufacturers can help customers reduce their environmental footprint and contribute to overall sustainability efforts.

Encouragement of responsible product use

Lastly, manufacturers are encouraging responsible product use to further promote sustainability. This includes educating customers on proper machine maintenance and care, such as regular cleaning and descaling, to ensure optimal performance and longevity. Manufacturers are also providing guidance on the responsible use of water and energy, such as brewing coffee in larger quantities to minimize water and energy waste. By encouraging responsible product use, manufacturers can help customers maximize the lifespan of their machines and minimize their overall environmental impact.

In conclusion, sustainable manufacturing practices are transforming the stainless steel espresso machine industry. Manufacturers are incorporating advanced technology and optimizing production processes to improve efficiency and save energy. The use of environmentally friendly materials, such as sustainably sourced stainless steel, and the reduction of waste generation through lean manufacturing principles further contribute to sustainability. Water conservation measures, lifecycle assessment analysis, and supply chain sustainability efforts are also being prioritized. Ensuring worker safety and well-being, promoting longevity and durability, responsible end-of-life disposal, and engaging customers through education and encouragement of eco-friendly practices are additional pillars of sustainable manufacturing. With these comprehensive initiatives, the future of stainless steel espresso machines is not only efficient and high-quality but also environmentally friendly and socially responsible.