Have you ever wondered how the type of boiler used in stainless steel espresso machines can impact the quality of your coffee? In this article, we will explore the various boiler types and their effects on the brewing process. From single-boiler machines to heat exchanger and dual boiler systems, understanding the role of the boiler is key to achieving the perfect espresso shot. So, grab your favorite cup of joe and let’s dive into the fascinating world of boiler technology!

Boiler Type and Stainless Steel Espresso Machines

When it comes to choosing an espresso machine, the type of boiler used can have a significant impact on the performance and functionality of the machine. Stainless steel espresso machines are known for their durability, longevity, and ability to produce high-quality espresso. In this article, we will explore the different types of boilers commonly found in stainless steel espresso machines, the advantages of stainless steel machines, and how different boiler types affect the overall performance of the machine.

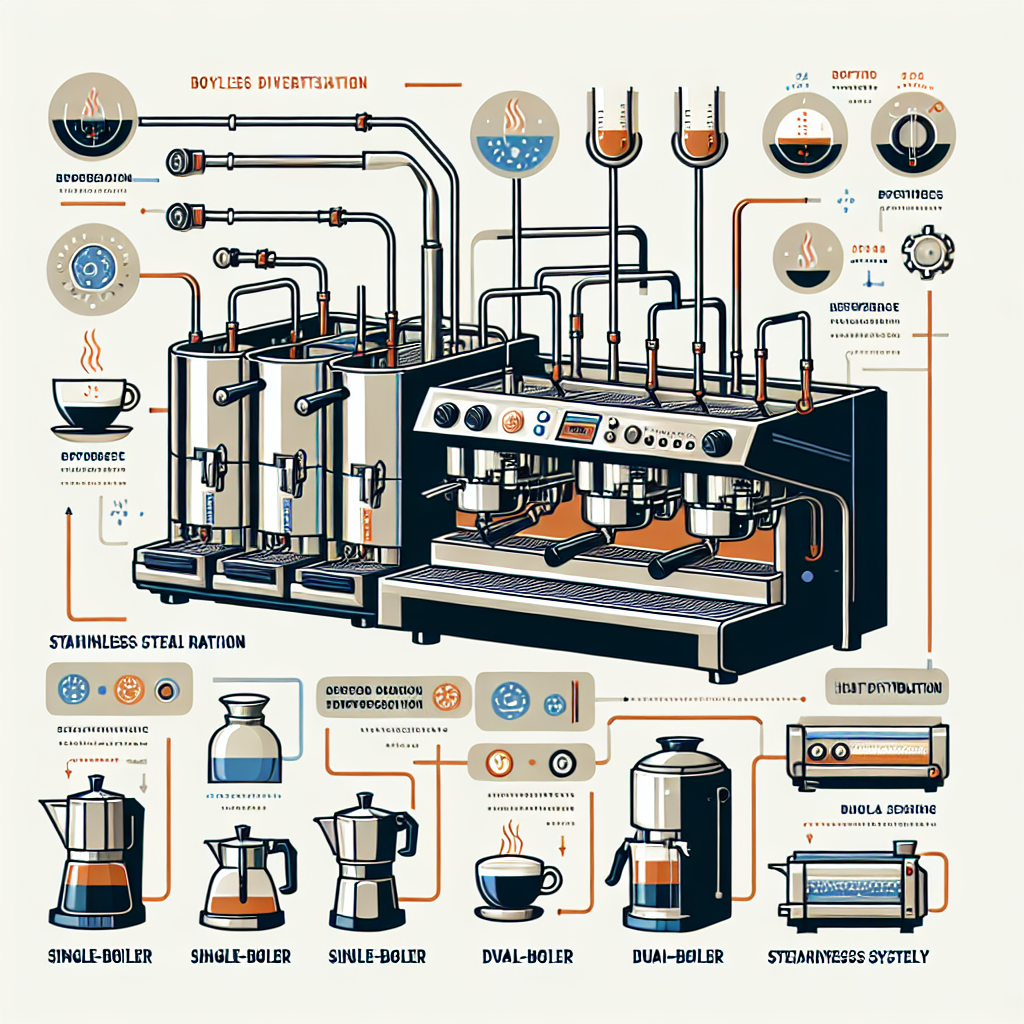

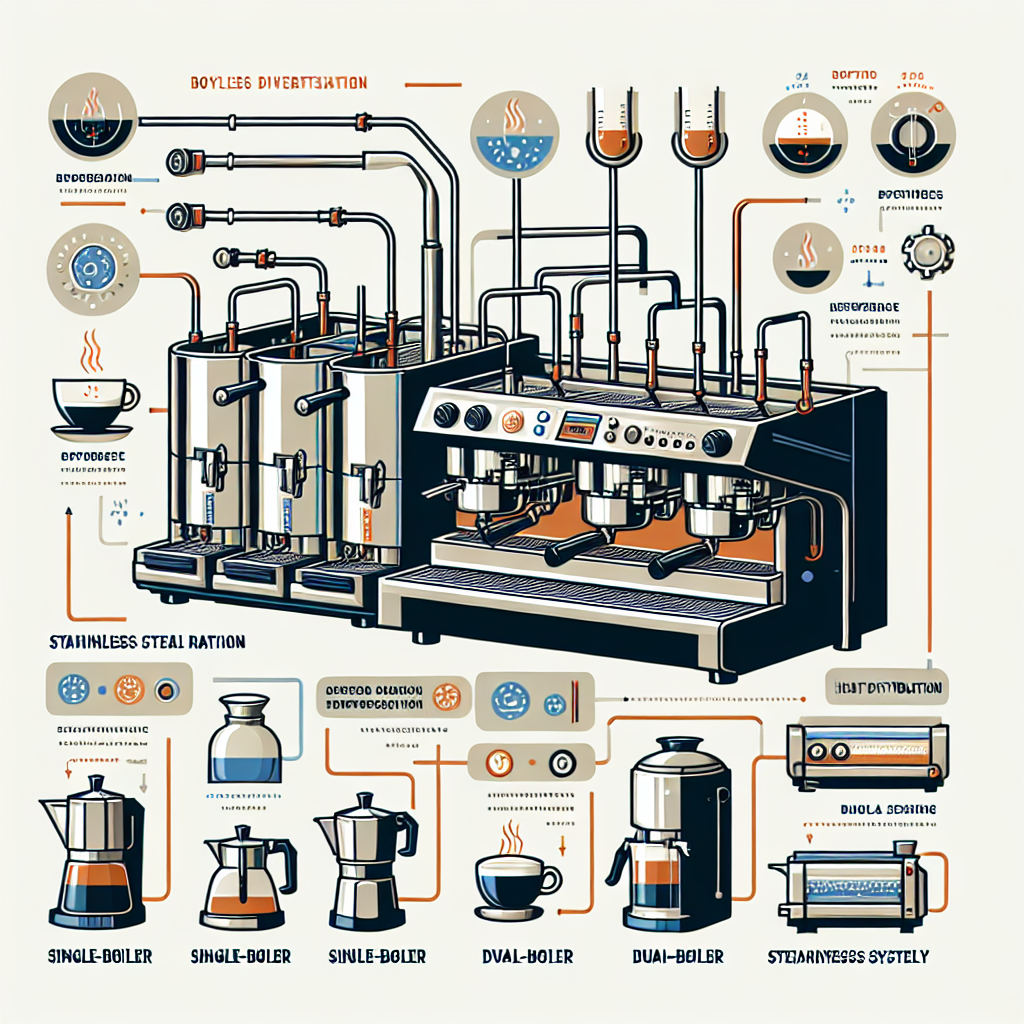

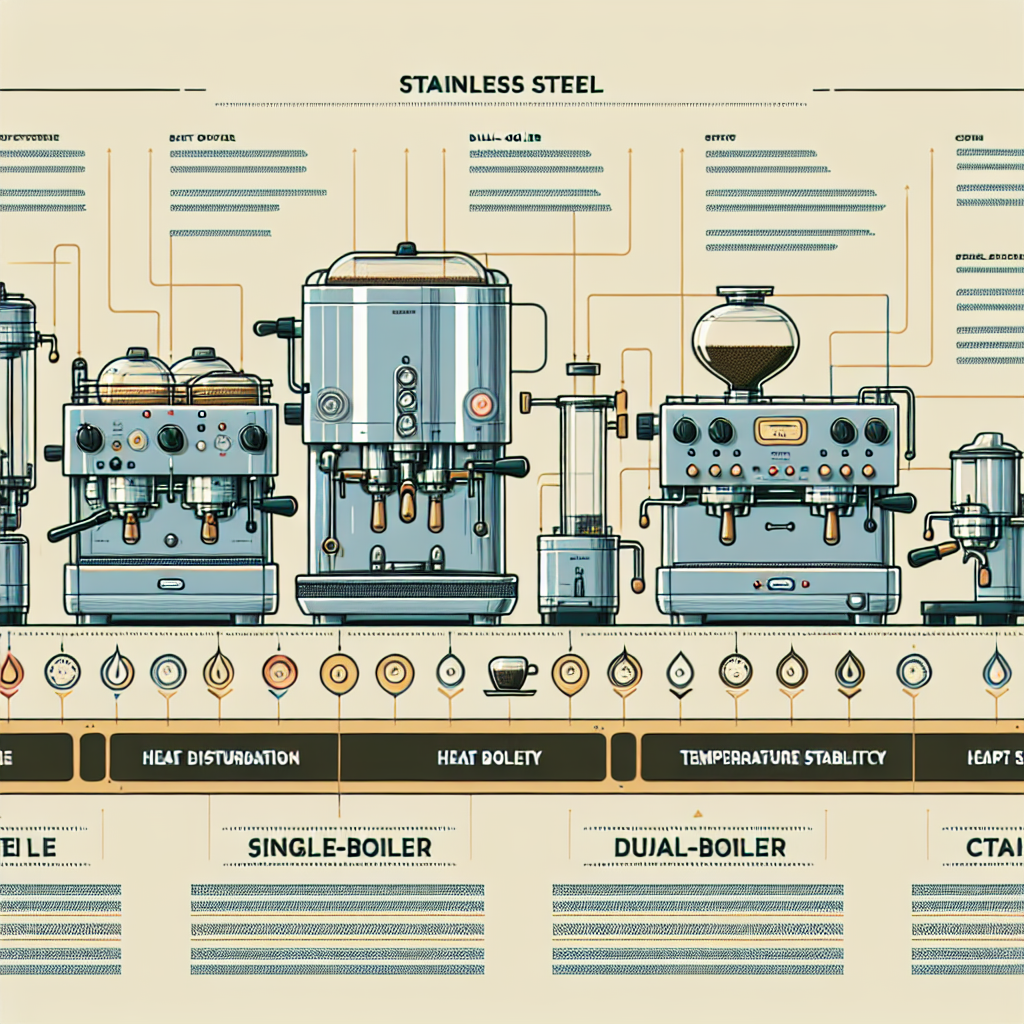

Overview of Boiler Types

Before diving into the details, let’s understand the three main types of boilers commonly used in espresso machines: single boiler, dual boiler, and heat exchanger.

Single Boiler

A single boiler espresso machine is designed with only one boiler, which is responsible for both brewing and steaming functions. This means that you cannot brew and steam simultaneously but need to wait for the boiler to switch between the two tasks. Single boiler machines are often more affordable and suitable for home use or small-scale operations.

Dual Boiler

dual boiler espresso machines, as the name suggests, come equipped with two separate boilers: one dedicated to brewing and the other for steaming. This allows for simultaneous brewing and steaming, making them ideal for busy cafes and those who require efficiency and speed in their espresso-making process.

Heat Exchanger

Heat exchanger espresso machines feature a single boiler but employ a different mechanism to provide both brewing and steaming capabilities simultaneously. The heat exchanger system utilizes a tube or coil within the boiler to heat the water for brewing, while at the same time, the steam is generated separately. This design allows for quick and efficient switching between brewing and steaming, making heat exchanger machines popular among professional baristas.

Single Boiler

Let’s explore the single boiler espresso machines in more detail.

Explanation of Single Boiler

A single boiler espresso machine has a single boiler that heats water for both brewing and steaming, but it cannot perform both functions at the same time. Instead, the boiler switches between brewing and steaming modes, which can cause a slight delay in the overall espresso-making process.

How Single Boiler Works

When you want to make espresso, the single boiler heats the water to the optimal brewing temperature. Once the boiling point is reached, the water is pushed through the coffee grounds to extract the flavor and create the espresso shot. When it’s time to steam milk, the boiler switches to steam mode, reaching a higher temperature required for frothing and steaming.

Pros and Cons of Single Boiler in Stainless Steel Espresso Machines

The main advantage of a single boiler machine is its affordability. These machines tend to be more budget-friendly compared to dual boiler or heat exchanger counterparts. Single boiler machines are also typically compact and suitable for home use, allowing you to enjoy professional-grade espresso at your convenience.

However, the main drawback of single boiler machines is their inability to simultaneously brew and steam. This can result in longer wait times between brewing and steaming tasks, which may not be ideal for commercial settings or when serving multiple cups of coffee in quick succession. Additionally, the temperature fluctuations during the switch between brewing and steaming modes can affect the overall quality and consistency of the espresso.

Dual Boiler

Now, let’s take a closer look at dual boiler espresso machines.

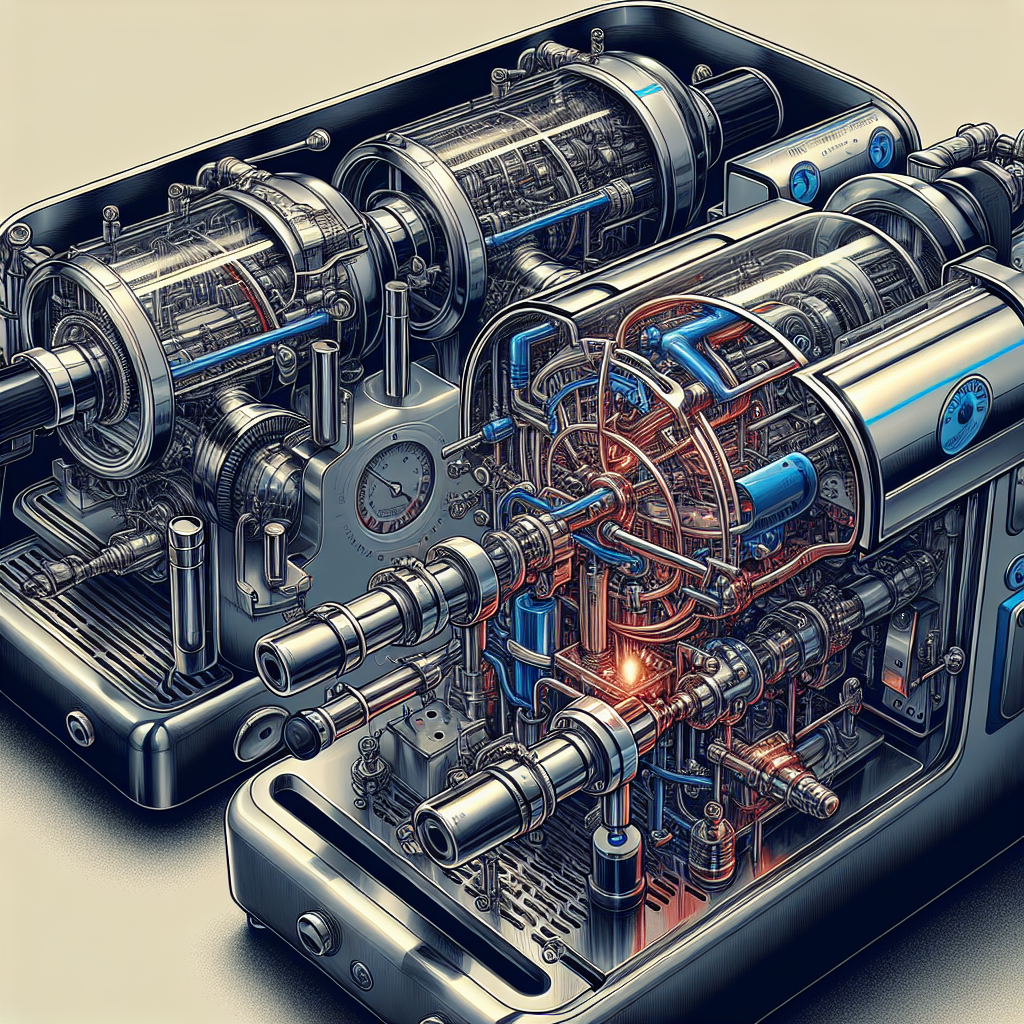

Explanation of Dual Boiler

Dual boiler espresso machines feature two separate boilers: one dedicated to brewing and the other for steaming. Having two boilers allows for simultaneous brewing and steaming without any interruptions or delays.

How Dual Boiler Works

With dual boiler machines, the brewing boiler maintains a constant temperature specifically optimized for extracting espresso. On the other hand, the steam boiler operates at a higher temperature, ensuring a sufficient supply of steam for frothing milk. This simultaneous operation allows you to brew espresso shots and steam milk simultaneously, enhancing the overall efficiency and productivity of the espresso-making process.

Pros and Cons of Dual Boiler in Stainless Steel Espresso Machines

The biggest advantage of a dual boiler machine is the ability to brew and steam simultaneously. This feature is particularly valuable in commercial settings or when you need to serve multiple drinks quickly. With a dual boiler machine, you can make espresso shots and steam milk at the same time, reducing wait times and improving workflow.

However, dual boiler espresso machines do tend to be more expensive compared to single boiler or heat exchanger options. The additional cost is justified by the enhanced functionality and efficiency they provide, but it may not be necessary for those who primarily use their machine for home use. Additionally, dual boiler machines may require more space in your kitchen due to the presence of two boilers.

Heat Exchanger

Finally, let’s explore the heat exchanger espresso machines.

Explanation of Heat Exchanger

Heat exchanger espresso machines utilize a single boiler but employ a different mechanism to provide both brewing and steaming functions simultaneously. These machines use a tube or coil within the boiler to heat the water for brewing, while steam is generated separately. The heat exchanger system allows for quick switching between brewing and steaming, offering increased efficiency.

How Heat Exchanger Works

In a heat exchanger machine, cold water enters the boiler and passes through the heat exchange tube or coil, where it is quickly heated to the desired brewing temperature. At the same time, steam is generated independently from the steam wand. This design enables baristas to brew espresso shots while simultaneously frothing or steaming milk.

Pros and Cons of Heat Exchanger in Stainless Steel Espresso Machines

Heat exchanger espresso machines combine the benefits of both single boiler and dual boiler machines. They offer simultaneous brewing and steaming capabilities without the higher price tag of a dual boiler machine. Heat exchangers are commonly found in commercial settings and are favored by professional baristas for their efficiency and versatility.

However, heat exchanger machines can be challenging to master, especially for beginners. Achieving consistent temperature control can be more difficult compared to dual boiler machines, as the heat exchanger system introduces additional variables. Additionally, there can be slight temperature fluctuations during use, which can impact the quality and consistency of the espresso.

Advantages of Stainless Steel Espresso Machines

Now that we have explored the different types of boilers, let’s discuss the advantages of stainless steel espresso machines.

Durability and Longevity

Stainless steel espresso machines are known for their durability and longevity. The stainless steel construction not only provides a sleek and professional look but also ensures that the machine can withstand the rigors of daily use. Stainless steel is resistant to rust, corrosion, and staining, which makes these machines a long-term investment for coffee enthusiasts.

Heat Retention

Stainless steel is an excellent conductor of heat, allowing espresso machines to quickly heat up and maintain stable temperatures. Unlike materials like aluminum, stainless steel has a higher heat retention capacity, ensuring that the water remains at the optimal temperature for brewing throughout the process. This results in consistently flavorful and delicious espresso shots.

Enhanced Flavor and Taste

The material used in the construction of an espresso machine can affect the flavor and taste of the resulting espresso. Stainless steel espresso machines are known to have a neutral flavor profile, which means that they do not impart any metallic or off-putting tastes to the espresso. This allows the natural flavors and nuances of the coffee beans to shine through, resulting in a more enjoyable and authentic espresso experience.

Aesthetics and Design

Stainless steel espresso machines are often chosen for their sleek and polished look. The stainless steel exterior adds a touch of elegance and sophistication to any kitchen or café setting. These machines are designed to be visually appealing, making them a statement piece and enhancing the overall aesthetics of your espresso setup.

How Different Boiler Types Affect Stainless Steel Espresso Machines

Now, let’s examine how the different boiler types can affect the performance and functionality of stainless steel espresso machines.

Temperature Control

Temperature control plays a crucial role in the extraction of espresso. The optimal brewing temperature is essential for extracting the flavors and aromas from the coffee grounds while avoiding over-extraction or under-extraction.

Different boiler types offer varying levels of temperature control. Dual boiler machines generally provide the most precise temperature control, as each boiler is dedicated to a specific function (brewing or steaming). This ensures that the brewing boiler maintains a consistent temperature throughout the extraction process, resulting in a more consistent and flavorful espresso shot.

Single boiler machines, on the other hand, may experience temperature fluctuations when switching between brewing and steaming modes. This can impact the overall taste and consistency of the espresso and may require additional attention to achieve the desired temperature.

Heat exchanger machines fall somewhere in between. While they allow for simultaneous brewing and steaming, the heat exchanger system introduces additional variables that can affect temperature control. Baristas need to understand and manage these variables to achieve optimal results.

Simultaneous Brewing and Steaming

The ability to brew and steam simultaneously is a valuable feature in espresso machines, especially in busy café environments or when serving multiple drinks quickly.

Dual boiler machines excel in this aspect, as the dedicated brew and steam boilers allow for seamless multitasking. With a dual boiler machine, you can extract espresso shots while frothing milk, reducing wait times and improving overall efficiency. This makes dual boiler machines a popular choice for high-volume espresso production.

Heat exchanger machines also enable simultaneous brewing and steaming by using a heat exchanger system. While not as precise as dual boiler machines, heat exchangers are still capable of delivering impressive performance. However, beginners or those who prioritize precise temperature control may find the learning curve steeper with heat exchanger machines.

Single boiler machines are not designed for simultaneous brewing and steaming. Instead, you need to wait for the boiler to switch between brewing and steaming modes, which can add time to the overall espresso-making process.

Brewing and Steaming Speed

The speed at which an espresso machine can brew and steam can be critical, particularly during high-demand situations or when time is of the essence.

Dual boiler machines excel in this aspect, as they allow for continuous brewing and steaming without any interruptions. Baristas can extract multiple espresso shots and froth milk simultaneously, significantly reducing the time needed to prepare drinks. This feature makes dual boilers ideal for busy commercial settings or when serving multiple customers quickly.

Heat exchanger machines also offer efficient brewing and steaming capabilities, allowing for quick switchovers between the two functions. While not as fast as dual boiler machines, heat exchanger machines can still keep up with the demands of most coffee shops or home use.

Single boiler machines, due to their sequential nature, may take longer to prepare drinks as you need to wait for the boiler to switch between brewing and steaming modes. This can be a drawback in time-sensitive situations or when serving a large number of customers.

Size and Capacity

The size and capacity of an espresso machine are important considerations, particularly if you have limited counter space or if you anticipate high-volume usage.

Dual boiler machines tend to be larger and may require more space in your kitchen or café setting. This is because they house two separate boilers, each with its own heating element. The larger size, combined with the increased capacity, makes dual boiler machines suitable for high-volume environments or those who require the ability to produce large quantities of espresso and steam milk continuously.

Heat exchanger machines are usually more compact compared to dual boiler machines. The single boiler with a heat exchanger system allows for efficient use of space without compromising on brewing and steaming capabilities. Heat exchangers are often a preferred choice for coffee enthusiasts with limited counter space or home baristas who prioritize versatility and efficiency.

Single boiler machines are generally the most compact and space-friendly option. Their smaller size makes them ideal for home use or situations where space is a premium. However, the smaller boiler capacity may limit the volume of drinks you can produce before needing to refill the water reservoir.

Maintenance and Cleaning

Maintenance and cleaning are essential aspects of keeping your espresso machine in top shape and ensuring its longevity.

Dual boiler machines typically require more maintenance due to the presence of two separate boilers. Regular descaling, backflushing, and routine cleaning are necessary to prevent the buildup of mineral deposits or coffee residue. While the cleaning process can be slightly more involved compared to other types, dual boiler machines also offer easier access to individual components for servicing or repairs.

Heat exchanger machines require similar maintenance procedures, such as descaling and routine cleaning. However, the heat exchanger system may introduce additional considerations. For instance, the heat exchange tube or coil needs regular cleaning to remove any accumulated coffee oils or mineral deposits that can affect the taste and performance of the espresso machine. Proper maintenance is crucial to ensure optimal performance and longevity.

Single boiler machines are typically easier to maintain and clean due to their simpler design. Regular backflushing, descaling, and cleaning of the portafilter and steam wand are recommended to keep the machine in optimal condition. However, the lack of separate boilers may require extra attention to temperature control and ensuring proper cleaning between brewing and steaming tasks.

Conclusion

In conclusion, the type of boiler used in a stainless steel espresso machine can have a significant impact on its performance, functionality, and overall brewing experience. Whether you choose a single boiler, dual boiler, or heat exchanger machine, understanding the advantages and limitations of each type is essential in finding the right espresso machine for your needs.

Stainless steel espresso machines offer durability, heat retention, enhanced flavor, and aesthetic appeal. The choice between different boiler types should consider factors such as temperature control, simultaneous brewing and steaming capabilities, brewing and steaming speed, size and capacity, and maintenance and cleaning requirements.

By carefully assessing your specific requirements and preferences, you can select the perfect stainless steel espresso machine with the right boiler type to elevate your coffee brewing experience and create café-quality espresso in the comfort of your own home or business.