In this article, you will learn all the essential tips and tricks on how to properly clean and maintain your micron gauge. Understanding the importance of keeping your micron gauge in top-notch condition is crucial for accurate and reliable measurements. From step-by-step cleaning instructions to essential maintenance practices, we’ve got you covered. So, grab your cleaning supplies and get ready to ensure the longevity and accuracy of your micron gauge. Let’s dive into the world of proper maintenance for your essential tool!

Why Clean and Maintain Your Micron Gauge

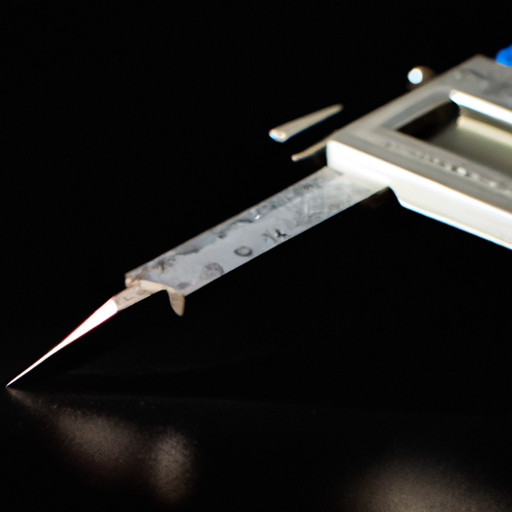

Keeping your micron gauge clean and properly maintained is crucial to ensure accurate readings and reliable operation. A micron gauge is a valuable tool used in various industries, such as HVAC, refrigeration, and automotive, to measure the level of vacuum or pressure in a system. By regularly cleaning and maintaining your micron gauge, you can optimize its performance and extend its lifespan. Neglecting maintenance can lead to inaccurate readings, reduced efficiency, and potentially costly repairs or replacements.

Importance of a clean and accurate micron gauge

Maintaining a clean and accurate micron gauge is essential for several reasons. Firstly, keeping the gauge clean helps to prevent debris, dust, and other contaminants from interfering with its operation. Any foreign particles can hinder the functionality of the gauge and compromise the accuracy of your readings. Secondly, a clean gauge ensures that the components, such as the sensor and display screen, are free from any obstruction or build-up that may affect their performance. Finally, regular cleaning and maintenance help to identify any potential issues and prevent them from escalating into more significant problems that may require professional assistance.

Effects of neglecting maintenance

If you neglect the maintenance of your micron gauge, several negative consequences can occur. One of the most significant effects is the compromise of accuracy. Without regular cleaning, the gauge may become clogged or the sensor may become dirty, leading to inaccurate readings. This can cause a multitude of issues, such as incorrect diagnoses, ineffective repairs, and poor overall system performance. Additionally, neglecting maintenance can result in a shorter lifespan for your micron gauge. A dirty gauge is more prone to wear and tear, requiring premature replacement. By properly maintaining your gauge, you can avoid these adverse effects and ensure optimal functionality.

Better performance and longer lifespan with regular cleaning

Regular cleaning of your micron gauge can significantly improve its performance and extend its lifespan. Cleaning the gauge eliminates any build-up or debris that may hinder its accuracy or functionality. By removing these obstructions, you can ensure that the gauge operates at its maximum potential, providing you with accurate readings that you can rely on for your work. Additionally, by maintaining a clean gauge, you reduce the likelihood of damage to internal components, thus prolonging the life of your gauge. Taking the time for regular cleaning and maintenance will ultimately save you time and money in the long run.

Essential Tools and Materials

To clean and maintain your micron gauge, you will need a few essential tools and materials. Here is a list of what you’ll need:

Screwdriver set

A screwdriver set will be necessary to disassemble the micron gauge, allowing you to access the internal parts for cleaning.

Cleaning solution

You will require a suitable cleaning solution to remove any dirt, grime, or contaminants from the exterior, sensor, and display screen of the gauge. It is important to use a cleaning solution that is compatible with the materials of your micron gauge and will not cause any damage.

Soft cloths or lint-free wipes

Soft cloths or lint-free wipes are ideal for gently wiping and removing debris from the gauge’s exterior, sensor, and display screen. These materials will not leave behind any fibers or residue that could interfere with the gauge’s operation.

Compressed air

Compressed air can be used to blow away any dust or debris that may be lodged in the internal components of the gauge. It is essential to be cautious and use compressed air in a well-ventilated area.

Rubber gloves

Rubber gloves are necessary to protect your hands from any chemicals in the cleaning solution and to prevent the transfer of oils or dirt onto the gauge during the cleaning process.

Safety glasses

Wearing safety glasses is crucial to ensure eye protection while cleaning your micron gauge. This will protect your eyes from any potential debris or splashes that may occur during the cleaning process.

By having these tools and materials ready, you will be well-prepared to clean and maintain your micron gauge effectively.

Step-by-Step Cleaning Process

Now that you have gathered the essential tools and materials, let’s walk through the step-by-step process of cleaning your micron gauge:

1. Disconnect the power and remove batteries

Before you begin cleaning, it is important to disconnect the power source and remove any batteries from the micron gauge. This will prevent any electrical shock or damage to the gauge during cleaning.

2. Disassemble the micron gauge

Using the appropriate screwdriver from your set, carefully remove the screws that hold the gauge together. Take note of the placement and order of the screws for easy reassembly later on.

3. Clean the exterior

Dampen a soft cloth or lint-free wipe with the cleaning solution. Gently wipe the exterior of the gauge, removing any dirt, grime, or fingerprints. Be careful not to get the cleaning solution into any openings or ports on the gauge.

4. Clean the sensor

Using a clean cloth or wipe, apply a small amount of cleaning solution to it. Gently wipe the sensor of the gauge to remove any dirt or debris that may have accumulated. Take care not to apply excessive pressure or damage the sensor in the process.

5. Clean the display screen

Similar to the steps above, use a clean cloth or wipe with a small amount of cleaning solution to clean the display screen. Wipe gently, ensuring that no streaks or residue are left behind.

6. Remove any debris or dirt from internal components

With the gauge disassembled, use compressed air to blow away any dust or debris from the internal components. Be cautious while using compressed air and do so in a well-ventilated area to avoid inhaling any particles or chemicals.

7. Reassemble the micron gauge

After ensuring that all the components are clean and dry, carefully reassemble the gauge by placing all the parts back in their original positions. Use the screws to secure the gauge, ensuring a snug fit. Take care not to overtighten the screws, as this may damage the gauge’s casing.

By following these step-by-step instructions, you can effectively clean and maintain your micron gauge, keeping it in optimal condition for accurate readings and prolonged use.

Proper Maintenance Practices

In addition to regular cleaning, there are several other maintenance practices you should follow to ensure the longevity and accuracy of your micron gauge:

Regular calibration checks

It is important to regularly calibrate your micron gauge as per the manufacturer’s instructions. Calibration helps to verify the accuracy of the gauge and make any necessary adjustments. By calibrating your gauge at regular intervals, you can ensure that it continues to provide accurate readings.

Keeping the gauge in a protective case when not in use

When you are not using your micron gauge, it is essential to store it in a protective case. A protective case prevents any damage or scratches to the gauge, keeping it in optimal condition.

Using protective covers for the display screen

To prevent any scratches or damage to the display screen, consider using a protective cover or film. These covers are designed to fit the specific size of the gauge’s screen and provide an extra layer of protection.

Avoiding exposure to extreme temperatures

Extreme temperatures can negatively impact the performance and accuracy of your micron gauge. It is advisable to store and use the gauge within the temperature range specified by the manufacturer. Avoid leaving the gauge in excessively hot or cold environments for prolonged periods.

Storing in a clean and dry environment

Lastly, be sure to store your micron gauge in a clean and dry environment. Moisture and humidity can cause damage to the gauge’s internal components, leading to inaccurate readings and shortened lifespan. Keep the gauge in a dry location to ensure optimal performance.

By incorporating these proper maintenance practices into your routine, you can prolong the lifespan of your micron gauge and ensure accurate readings for years to come.

Dos and Don’ts

To further guide your cleaning and maintenance efforts, here are some essential dos and don’ts to follow:

Dos:

-

Follow manufacturer’s instructions: Always adhere to the guidelines provided by the manufacturer for cleaning and maintenance procedures. Following these instructions ensures that you do not cause any damage or void any warranties.

-

Use appropriate cleaning solutions: Use cleaning solutions that are specifically recommended for use on your micron gauge. Avoid using harsh or abrasive chemicals that may corrode or damage the gauge’s components.

-

Handle with care: Take care when handling the micron gauge, especially when disassembling or reassembling it. Apply gentle pressure and avoid excessive force to prevent any damage.

Don’ts:

-

Use abrasive materials: Never use abrasive materials, such as steel wool or scrub brushes, to clean your micron gauge. These materials can scratch or damage the gauge’s surfaces and components.

-

Apply excessive force: Avoid applying excessive force when cleaning or handling the gauge. Doing so may damage delicate components or cause misalignment, affecting the gauge’s accuracy and functionality.

-

Use harsh chemicals: Do not use harsh chemicals or solvents that are not specifically recommended for use with your micron gauge. These chemicals can cause damage to the gauge’s surfaces or components.

By following these dos and don’ts, you can ensure that you are taking the necessary precautions to clean and maintain your micron gauge properly.

Tips for Troubleshooting

Sometimes, even with proper cleaning and maintenance, issues may arise with your micron gauge. Here are some troubleshooting tips to help you address common problems:

Check for loose connections

If your gauge is not turning on or displaying inaccurate readings, check for loose connections. Make sure all cables, wires, and batteries are securely and correctly connected.

Ensure proper battery installation

If your gauge is powered by batteries, ensure that they are installed correctly. Reversing the battery orientation can result in the gauge not functioning properly.

Inspect the sensor for damage

If you notice inconsistent or abnormal readings, inspect the sensor for any signs of damage or obstruction. Clean the sensor carefully and check for any loose or damaged components.

Calibrate if readings seem inaccurate

If you suspect that your micron gauge is providing inaccurate readings, it may be necessary to recalibrate it. Follow the manufacturer’s instructions for calibration or consult a professional if needed.

Refer to the manufacturer’s troubleshooting guide

If you encounter persistent issues or are unsure how to address a problem, refer to the manufacturer’s troubleshooting guide. They often provide specific solutions and guidance for common issues that may arise with their micron gauges.

By implementing these troubleshooting tips, you can resolve common problems and ensure the proper functioning of your micron gauge.

When to Seek Professional Assistance

While regular cleaning and maintenance can address many issues with your micron gauge, there may be instances where professional assistance is required. Here are some situations where it is advisable to seek help from a professional:

Persistent issues after troubleshooting

If you have followed the troubleshooting tips and are still experiencing persistent issues with your micron gauge, it may be necessary to consult a professional. They have the expertise and specialized equipment to diagnose and resolve more complex problems.

Suspected damage to internal components

If you suspect that there is damage to the internal components of your micron gauge, it is best to leave the inspection and repairs to a professional. Attempting to repair internal damage without the proper knowledge and tools can exacerbate the problem and potentially render the gauge irreparable.

Lack of expertise or time for proper maintenance

If you lack the necessary expertise or time to perform proper cleaning and maintenance on your micron gauge, it is recommended to seek professional assistance. They can ensure that your gauge receives the care it needs to maintain accuracy and longevity.

By recognizing when professional assistance is necessary, you can avoid further complications and ensure the optimal performance of your micron gauge.

Conclusion

Regular cleaning and maintenance are essential for enhancing the performance and lifespan of your micron gauge. By following the recommended cleaning procedures and maintenance practices, you can ensure accurate readings and reliable operation. Remember to always use the appropriate tools, materials, and cleaning solutions, and handle your gauge with care. Regular calibration, proper storage, and adherence to manufacturer’s instructions are key to keeping your gauge in optimal condition. By investing time in proper maintenance, you can rely on your micron gauge for accurate measurements and enjoy its longevity for years to come.